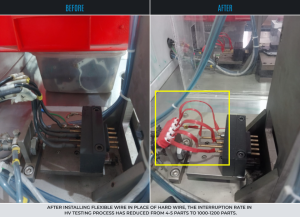

Improvement in reliability of Ducato Auto HV testing by addressing issues caused by loose connections

PROBLEM STATEMENT

The Ducato Auto HV testing process encountered frequent interruptions due to loose connections after a certain cycle count, leading to inefficiencies and delays in operations.

PROBLEM ANALYSIS

The occurrence of loose connections during HV testing was identified as a recurring issue. The stiffness of the existing hard wire contributed to the issue, as it caused stress and degradation in the connections over time.

ROOT CAUSE

The wire harness used in the setup was too rigid, leading to excessive stress at connection points after repeated cycles, which eventually resulted in loose connections.

KAIZEN IDEA

Replace the existing hard wire with a more flexible wire to reduce stress on connection points, ensuring consistent performance and preventing loose connections over time.

COUNTER MEASURE

Replace the rigid wires with flexible wires across all affected setups.

Test the updated system to confirm the issue has been resolved.

Provide training for staff on proper wire handling to maintain connection reliability in future cycles.

BENCHMARK

Zero interruptions in HV testing due to loose connections after implementing flexible wires.

Achieve uninterrupted performance over (Insert target cycle count) cycles consistently.

QANTITATIVE

Improved system reliability: Eliminates interruptions in HV testing due to loose connections.

Enhanced performance consistency: The use of flexible wires ensures stable connections over a greater number of cycles.

Increased operational efficiency: Reduces downtime and ensures smoother testing processes.