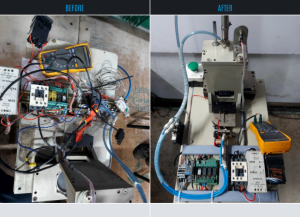

Modification of mV Drop Machine for Improved Wire Traceability, Systematic Arrangement, and Enhanced Reliability

PROBLEM STATEMENT

The existing mV Drop machine had issues with wire traceability, lacked systematic arrangement, and experienced loose connections, leading to increased risk of breakdowns and faulty readings.

PROBLEM ANALYSIS

The absence of an optimized wire arrangement made it difficult to trace connections efficiently. Loose connections contributed to frequent breakdowns, while the disorganized setup increased the chances of errors and faulty readings during operation.

ROOT CAUSE

Unsatisfactory wire arrangement caused confusion and inefficiencies in traceability.

Loose connections due to inadequate design and maintenance practices led to reliability issues.

The setup lacked modifications to meet the demand for improved accuracy and performance.

KAIZEN IDEA

Modify the mV Drop machine to ensure easier wire traceability and systematic arrangement. Address loose connection issues and implement measures to minimize faulty readings.

COUNTER MEASURE

Reorganize the wire layout for improved traceability and systematic arrangement.

Replace or secure connectors to prevent loose connections.

Conduct thorough testing of the modified mV Drop machine to validate enhanced reliability and reduced error rates.

Train the operators on handling and maintaining the improved system.

BENCHMARK

Zero breakdowns caused by loose connections.

Reduction in faulty readings by (Insert target percentage).

Achieve 100% wire traceability in the updated system.

QUANTITATIVE

Improved wire traceability: Easier identification and maintenance of connections.

Reduced breakdown risk: Secured connections minimize downtime.

Minimized faulty readings: Systematic arrangement and modifications enhance accuracy.

Enhanced operational efficiency: The optimized design leads to smoother workflows.