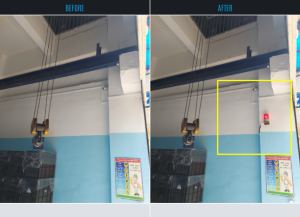

Enhancement of operator safety through the introduction of an alarm system interlocked with the overhead crane.

Problem Statement

Previously, the overhead crane operated without an alarm system, leading to potential safety risks as operators might unknowingly stand under a moving crane while it was in use.

Problem Analysis

The absence of an alarm system in the overhead crane operation process increased the likelihood of unsafe practices. Operators were unaware of the crane’s movement, especially while lifting or lowering loads, thereby posing a significant safety hazard.

Root Cause

Lack of an integrated warning system (alarm and light) in the overhead crane setup to notify operators of its operation.

Kaizen Idea

Install an alarm system interlocked with the crane. The alarm will sound, and a warning light will activate whenever the crane is lifting or lowering, whether in a loaded or unloaded state. This ensures operators are alerted and prevents them from standing beneath the crane.

Counter Measure

Implement an alarm system with a light interlock on the crane.

Conduct a trial run to verify the effectiveness of the system and ensure it meets safety standards.

Train crane operators and shop floor staff on the proper response to the alarm system for maintaining a safe environment.

Quantitative

Improved operator safety: The alarm system reduces the risk of accidents by alerting operators and keeping them away from hazardous areas.

Increased awareness: Operators are now immediately notified of crane movements, creating a safer working environment.

Compliance with safety standards: The enhanced setup aligns with modern safety protocols and demonstrates a commitment to workplace safety.